If you pour your own bullets*, you’ll be faced with a few options for getting them ready to fire. Poured lead bullets, as opposed to the FMJs you purchase from your friendly neighborhood gun dealer, need to be lubricated before you can fire them. This is to cut down on the leading of your barrel and, in a worst case, to ensure that the bullet doesn’t get stuck in your barrel. Such a result is, as they say, bad.

The easy way around the problem of stuck bullets is to choose Lee molds, which pour a perfect sized bullet, then to tumble-lube them using a liquid alox lube that covers the whole bullet evenly. We’re going to do things the hard way, using Lyman cast iron molds and a Lyman 4500 Lube Sizer.**

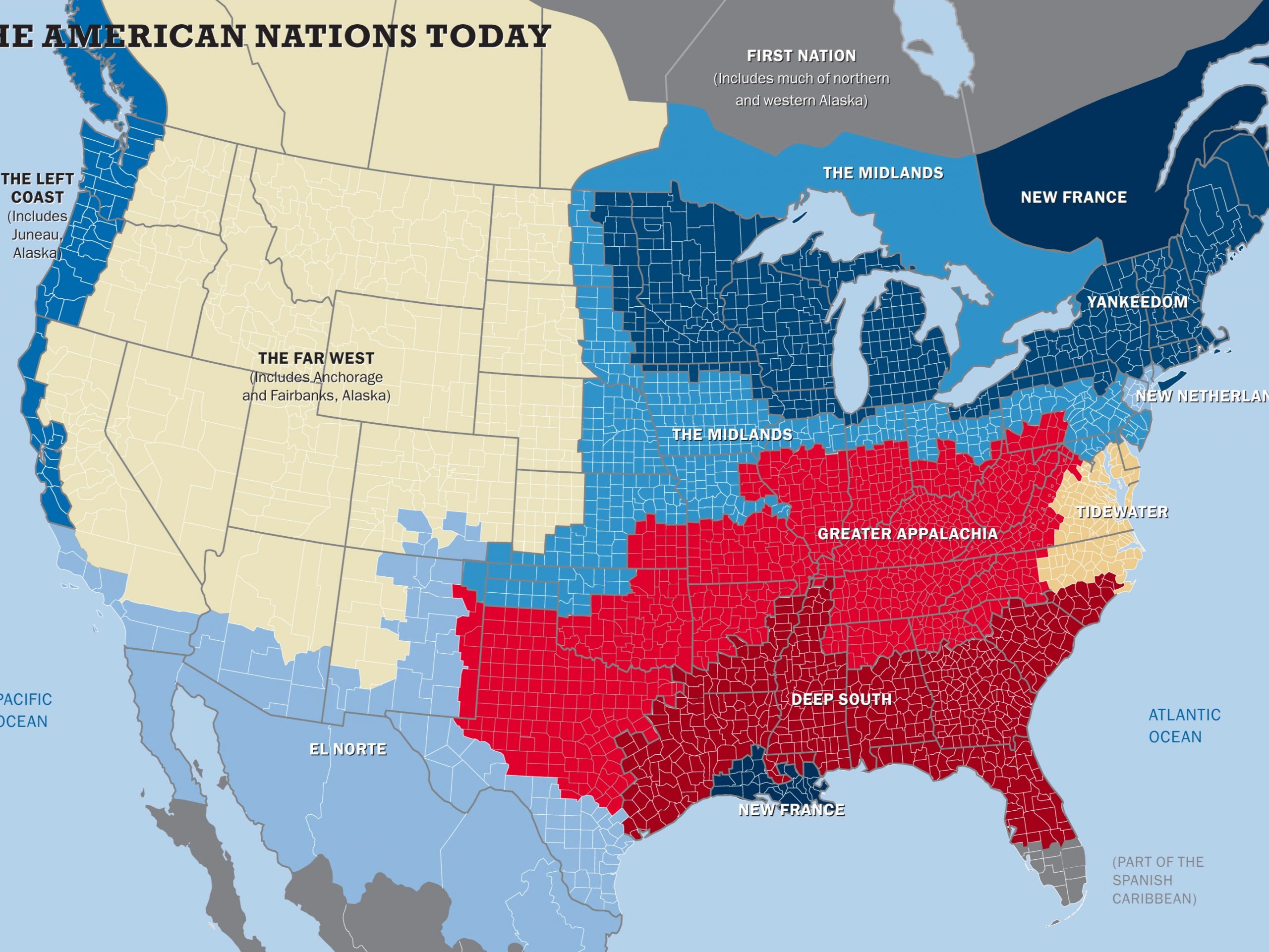

Pictured above is a 357 Magnum / 38 Special bullet I poured in a Lyman Mold #357446. As you can see, it doesn’t measure .357, but .361 inches across. It also has grooves that need some lube in them for this bullet to shoot properly from our gun. Enter the Lyman 4500, the press into which we will place the cast bullet to solve both problems with a pull and a twist.

I generally only size and lube enough for what I’m loading in any given day. Especially when using soft lubes, bullets that have been lubed can be sticky and messy and can attract a lot of dust. So while I’ll pour as many as I can in one sitting, I just save the bullets in a peanut butter jar until I’m ready to load. Then I’ll size, lube, and load in one sitting.

Luckily, setting up the Lube Sizer takes just 4 simple steps:

- Attach it to your bench. It has two holes in its base through which a couple of carriage bolts will pass easily.

- Fill the chamber with lube. If you use a hard lube, you’ll need to put the heater element*** in at this point to warm the lube. Now crank the stopper down with the included ratchet until you meet just a little resistance.

-

Attach the top punch

Install your swage (sizing) die. The swage die is a steel tube with a plunger and a few holes through which lube is going to flow. I like my 38 Specials at .358 inches across, so we’ll choose die… wait for it… 358. There’s a black hexagonal nut that holds it in place. Make sure you screw this down with your fingers first instead of using the hexagonal wrench so you don’t cross thread it. That’s fairly easy to do. - Insert your top punch. The top punch is a piece of metal that’s shaped like the top of the bullet and helps it to keep its shape as you force it through the sizer. If you use the wrong top punch, you can malform your bullet, so we need to make sure we have a punch that will seat properly. Fortunately, Lyman dies make this process easy, because the mold number (in our case 357446) corresponds to the bullet’s size (357) and the top punch we’ll use (446). Unfortunately, I don’t have a Lyman #446, so I’ll use an RCBS #429, which is pretty much the same thing.

OK, now that our lube sizer is set up, we are ready to size and lube a few bullets, a process even easier than setting up the lube sizer:

- Place the bullet point up in the middle of the sizing die.

- Pull the handle down, pressing the bullet into the die. It’s now sized properly.

- Give the lube ratchet about a quarter turn counterclockwise. This will force lube into the grooves of the bullet through the holes in the die.

- Push the handle up, ejecting the bullet. Check your bullets to make sure you’re getting an even lube all the way around, and especially that the top groove is filled. If it’s not even, you can adjust the plunger under the swage die or make your ratchet turn a little longer, up to 1/3 or even 1/2 crank. If that doesn’t fill the grooves with lube, turn the heat on – you may be using a hard lube without heating it properly. That’s bad, not only because it won’t lube your bullet but because the pressure created by hard lube can crack the base of the lube sizer. Always have the heat on when using hard lubes.

.358″, just what we wanted.

Finally, measure your first bullet to ensure that it’s the width you were expecting. This should be a really, really rare problem, as swage dies are almost never mis-sized. What is more likely is that through laziness or oversight you have the wrong die in the swage press, an easy mistake to make when everything is covered with lube. But the wrong size bullet in your gun will be far worse than the time wasted measuring the bullet in the first place. So double-check just to be on the safe side.

Now, load ’em up and happy hunting!

* Bullet pouring aficionados spell this word “boolit”, which would be annoying in the present context. So you get the unpretentious if correct spelling.

** Which, despite its name, does not size lube.

*** The difference between the Lyman 450 Lube Sizer and the 4500 is that the latter includes a heating element. Otherwise, all parts should be interchangeable.

Excellent article. Lots of Chili.

5