Editor’s note: The following is extracted from Shots Fired in Anger: A Rifleman’s-Eye View of the Activities on the Island of Guadalcanal, by Lt. Col. John B. George (published 1947).

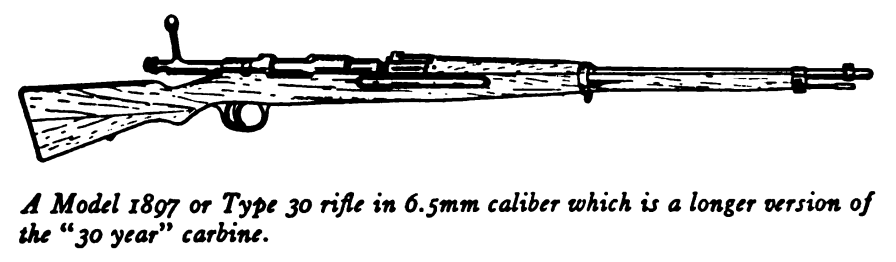

The “Thirty Year” Carbine

One of the most interesting weapons of the obsolete group which were found on Guadalcanal was the Thirty Year Carbine (and rifle). We ran into limited numbers of them in the early days of the Mount Austen operation, and a few more when we arrived at Cape Esperance. At first glance they were easily distinguishable from other Japanese shoulder weapons, and a quick examination of one gave me the opinion that they had likely been the immediate predecessors of the Arisaka series.

As carbines they were welcome to us, and several men in our column who had lost weapons during a river crossing incident armed themselves with the short and handy little weapons.

It would have embarrassed some of our American weapons and equipment designers if they had been able to see my column during the latter days on Guadalcanal. Half of my men had Japanese haversacks; all of them had Jap shovels and water bottles. It seemed a little strange to me to see our men armed and equipped in such varied fashion — to see one of my men go on guard or sentry duty and stand post with a Jap carbine, wearing a Jap leather belt with a set of cartridge boxes attached.

In some way, one of the corporals in my platoon had got hold of a Thirty Year Carbine in perfect shape — and had used it with good effect during the last few days of patrol activity on the Tanamboga River. When he was off duty, I borrowed the weapon and looked it over carefully, firing a few shots with it at sharks swimming in the shallow water out in front of my little seaside lean-to.

Superficially, it was a beautiful little gun. It was of .256 caliber, of course, and weighed about seven pounds. The barrel length was nineteen inches, and the whole gun measured thirty eight inches. The front sight was of barleycorn variety with sideguards provided and a dovetailed semimovable base which could be driven to and fro to obtain a basic lateral zero. This sight, as far as I could tell, was exactly the same as the one on the Arisaka. The folding leaf rear sight was graduated from five hundred to fifteen hundred meters, and when it was lowered, a battle sight notch came into position and supplied a 400 meter setting. (Apparently the Japanese of that period gave little thought to the advantages of being able to obtain an absolute zero at shorter ranges; as in the case of sights on other Japanese shoulder weapons, the leaf of the rear sight failed to provide any allowance for bullet drift.)

The operation of the rear sight was the same as the Arisaka. The open notched “drift” slide had a spring loaded lever lock on the right side which was scored on the surface for easy finger-grip; its lower tip was forced inward by the action of the spring where it would engage in the appropriate notch of a series (one for each hundred meters of range) which had been cut at intervals into the right side of the leaf. The lowering and raising of the leaf was accomplished by the standard hinge-and-flat spring system. When lowered, the leaf was engaged at its forward end by a stud which fit the forward (upper) inside cut of the leaf to brace it against shock or strain. The fixed rear sightbase was fitted around the barrel about one and three-quarter inches forward of the receiver. As with the Arisaka, this was a measure taken to sharpen up definition of the open notch rear sight by placing it at a greater distance from the firer’s eye.

The upper band, which held the characteristically heavy duty Jap bayonet stud was stoutly made and fitted around the barrel with very little clearance, once again attesting to the high regard given to bayonet tactics by the Japanese. The forend tip, which in the case of the Springfield is left sticking out bare with the end- grain of the walnut free to pick up moisture, was neatly capped with a metal plate, drilled for the cleaning rod.

The rifle cleaning rod, which the Japs have the good sense to put on all of, their standard rifles and carbines, was held in place by a spring loaded lever which was positioned at six o’clock on the forend tip, extending about three inches back from the upper band. The rod was of conventional Japanese design, and threaded for the excellent Japanese jag-type tip. On the particular weapon examined, the rod handletip was of brass, and enlarged to form a bore filling slug with a hole drilled in the very end, which was also used as a tool for the disassembly of the bolt.

The lower band was massively constructed, with the sling loop fitted on the right side to permit the rifle to be handily carried. It could be slung diagonally across the back by mounted cavalry and by Infantrymen who need both hands free for carrying or climbing. One unsolvable mystery, as far as I am concerned, is provided by the fact that the sling was swiveled to the right side of the weapon. This meant that the bolt would have to be raised while the weapon was slung to keep it from grinding into the soldier’s short ribs. This lower band was held in place against the forward shoulder of the enlarged rear portion of the forearm by an inletted spring-and-pin arrangement similar to that used on the Springfield; only it was much heavier in construction, and of twin design (i.e. there was a spring inletted on each side — one at 3 and one at 9 o’clock). Some small excuse for this extra weight and work may have been provided by the fact that the band, unlike the Springfield’s, was of solid and fixed construction, with no constricting takeup afforded by the use of a tightening screw; and it therefore needed this double support to prevent its rocking forward while the full weight of the weapon would be dangling on that “swivel” as the concerned soldier took his horse over some rough country.

Both upper and lower bands differed slightly from those on the Arisaka carbine in the fact that neither of them were adapted to fit over a handguard — because the Thirty Year Carbine had no handguard. The rear sling swivel was of the same design used on the Springfield and other rifles, but it was screwed into the right side of the buttstock, centered about four inches upward (forward) from the buttplate and about two and one-quarter inches below the top of the comb.

The buttplate was a heavy, well-finished cast steel affair with the top extended forward and inletted into the stock so that one screw could be placed pointing downward, making it almost impossible to wrench the buttplate off to the rear in any sort of a field accident. The other screw was placed in the toe, about an inch from the bottom tip. The plate was smooth finished, very slightly concave, and rather larger than is generally thought necessary for a military carbine of light caliber. It had no trap arrangement, and actually needed none — what with the cleaning rod on the weapon and the Japanese procedure of carrying cleaning equipment in the compartments and outside loops of their cartridge pouches.

The stock of this particular carbine was made of wood with a texture very similar to the poorer grades of American walnut and it was of rather thick, one-third pistolgrip construction. As in the case of a few Arisakas I have seen, the entire stock proper was of a single piece of wood, without the usual Japanese artifice of fitting an extra piece to fill out the lower third of the buttstock. The metal of the upper and lower tang surfaces was extended to the rear, however, just as in the case of weapons with the two piece stock. This instance would tend to nullify the concept that the rearward extension of metal was a feature incorporated solely for the purpose of binding together the forward part of the two piece stock; especially when it is realized that the Thirty Year Model was designed prior to the Arisaka. It is rather more likely that the rearward extension of metal was for the combined purposes of strengthening the stock at its inherently weak grip portion and at the same time increasing the area of rearend wood and metal contact to help take up the recoil. With the soft woods available to the Japanese, it is doubtful if the recoil shoulder system of recoil absorption — as used in the Springfield and the original M-98 Mauser — would have proven satisfactory for their weapons. Most likely the metal parts would have set back if this system were used.

The fit and finish of the particular stock which I examined were tighter and finer than those normally seen on Japanese ordnance products, and the same compliment can be paid its fittings, which were carefully polished and blued. The short forearm space betwixt receiver and lower band was inevitably graced with a short pair of finger grooves, which have been classically designated “hog wallows” by the late E. C. Crossman; and this is the only weapon I have seen on which their existence might have been justified. The carbine was a military weapon which might have to be fired at rapid fire rates for sustained periods, heating the barrel considerably — and there was no handguard; therefore the finger grooves might serve the purpose of reminding a man to grip the lower stock rather than let his fingers curl naturally around the barrel and fry on the tips.

More than likely, though, the Japanese just overlooked the importance of a handguard, and failed to provide one. The finger grooves also appear on their rifles which do have guards, (and all of their later weapons were equipped with guards). After a sufficient number of years’ experience, it seems, all ordnance departments come to realize the importance of keeping parts of the soldier from coming into contact with bare metal parts which are liable to be heated by friction and combustion.

The trigger guard and floorplate assembly, including the joined rear grip extension piece are almost exactly the same pattern as on the Arisaka. The floorplate latch is similar, too. All are heavily built, and they are rigidly held in place by three screws, the two forward ones being inserted from the underside, of course; and the rear one going through from the top, having its head seated in the upper tang piece (upper receiver extension piece).

The magazine, follower, and follower spring are all slight modifications of the Mauser, and are therefore similar to the Springfield, Enfield, and others. As far as I could make out, those on the Thirty Year Carbine were exactly the same as on the later Arisaka. The width of the magazine well, of course, was designed to stagger the cartridges. The receiver bridge has the conventional positioning cuts for holding the “charger” properly while the cartridges are thumbed down into the magazine.

The receiver is inordinately long for a weapon of its cartridge length. Parts of the “lengthening” occurred in front, where the receiver ring is actually more than two full inches in length and even exceeds that of the Arisaka by three-eighths. Part of it occurred in the rear — equaling the equivalent “stretching” of the Arisaka. Overall, the receiver exceeds the length of the 8mm Mauser by about seven-eighths of an inch. The forward lengthening of the receiver ring is — in a way — a necessity with this weapon, because of the peculiar ejector and bolt face system used. The rearward extension of the receiver tube serves a purpose too. It eliminates the cramping fault of the Mauser.

The carbine does not have a buildup of ejector and bolt stop mechanism on the left rear of the receiver; the only thing showing outside is a simple spring loaded lever, which when not depressed by the firer to allow removal of the bolt, always remains with a heavy forward surface pointing inward and blocking the left lug race, to firmly halt the bolt’s rearward travel. But strangely, it does not come directly to bear against the left locking lug. It is struck instead by the rear shoulder of a uniquely designed ejector, which rides forward with the bolt, remaining constantly in the left lug race. This ejector in turn strikes the rear surface of the left locking lug, after slight further travel of bolt to the rear — (about three thirty-seconds of an inch). The peculiar construction of the ejector, which, viewed from above, shows a cut in its right side as deep as the outward projection of the left lug, and about three thirty-seconds of an inch greater in length. This discrepancy provides the leeway to permit a good hard ejector thrust (or “blow”), and it constitutes the slack space which has to be closed up by the rearward movement of the left lug before the bolt reaches its final rearmost position.

The trigger and sear mechanism offer nothing new to change the regular Mauser military mechanism. They provide the double pull; however, the takeup portion of the pull is very short, with the trigger moving only a sixteenth or so before the harder portion of the squeeze begins.

In function the weapon differs considerably from the M-98 Mauser. The magazine loading is the same, and the initial ramping of the cartridge into the chamber is very little different, but there is no camming action on the final closing motion (downward movement of the bolt handle). The round is finally seated in the chamber by hand pressure on the bolt alone, which pressure is resisted not only by any tight fitting, oversize or dirty cartridges, but also by the tension of the rather powerful firing pin spring — for the cocking action is also accomplished during the forward stroke of the bolt. This, of course, is not good.

The firing of the cartridge is the same as with the Mauser and the lock against backthrust is almost identical. Two forward lugs, which rotate 90° from travel to lock positions, do all of the work. The left lug of these two is smaller, protruding only half as far as the right. This is a measure to allow space for the unusual ejector, previously mentioned, which fits over the lug during the forward and backward bolt travel.

At first glance, the bolt itself appears approximately the same as the Arisaka — nearly the same as the Mauser M-98. Its overall length, completely assembled, matches that of the M-98 8mm Mauser (as withdrawn from the rifle, with firing pin back); its bolt handle, the square base of which serves as a safety lug, is the same distance to the rear; and its diameter is roughly the same.

A second look, however, discloses great differences in both appearance and function from the Mauser, Springfield or Arisaka. At the rear, the firing mechanism includes a hook which serves as safety and cocking piece, projecting upward and blocking the line of sight when locked, and pointing to the left when otherwise. The “safety” position or “locked” position of this device is in reality an uncocked position, for in locking the weapon on “safe” this “safety-lever cocking-piece” is eased nearly all of the way forward. There it is held slightly to the rear by an arrangement in the rear of the bolt, so that the firing pin will not rest against the cartridge primer. Another difference in appearance is provided by the absence of the usual Mauser extractor along the right side of the bolt. The Thirty Year-type extractor is fitted into the bolt facepiece, with its inch-long spring completely concealed within the bolt thereby dispensing with the need for an extractor collar. With no camming action at all in the extraction operation, but only direct hand-pull instead, the Thirty Year extractor would not need to be so strong. If a cartridge should become badly stuck in this weapon, the firer would most likely have to knock it out with a cleaning rod anyway (he could, of course, set the butt on the ground and apply a heel to the bolt handle — in order to make “something” give). This feature of design is a definite disadvantage, and it makes the weapon highly critical of ammunition.

The bolt has no guide rib, but with the long-radiused support given by the lengthy receiver, none is needed. The very rear of the bolt proper (a complete circle) is enlarged considerably in diameter over the rest, apparently to provide the firer with protection from gases escaping back along the lug races. Protection from ruptured or perforated primer gases, which would otherwise course back through the inside of the bolt, is fairly well provided for by a hole drilled at two o’clock (closed position) some three-quarters of an inch to the rear of the locking lugs. Further protection is given by a tightly fitted Mauser type shoulder on the firing pin rod and an enlargement of the upper sear engagement which would help prevent the firing pin from being driven, Springfield-wise, back into the firer’s face.

Back near the handle there are two cuts on the body of the bolt which serve to perform an important safety function. One of them will not permit the weapon to be fired until the bolt is fully locked at which time the cut provides leeway for upward movement of the stud which when forced down acts to prevent accidental dis charge. The other cut provides the stud with leeway at non-critical times — when the weapon would not fire on other accounts. Without these, this carbine would be very dangerous to use, for with no camming action at all on the closing stroke it could easily be fired when the bolt would be only partially locked forward; in which case the firer would certainly suffer serious, if not fatal, injury.

The receiver ring is perforated by two gas vents, both visible on the top of the ring, which completed the gas precautions taken throughout the weapon. The Japanese have treated this problem with great care in the case of nearly every rifle they designed, probably because of rather low standards of ammunition uniformity which now and then cause excessively high breech pressures.

The most radical difference from the Mauser action in the whole rifle is the false, non-rotating bolt face — a device which possesses a few theoretical advantages, but which does much to complicate an otherwise simple and rugged action. The foremost three-eighths of an inch of bolt length on the Thirty Year Model is not an integral part of the bolt. It is a “false face,” attached by means of a metal projection to the rear which fits into the forward end of the bolt body proper and is held in place by a lug. The extractor and ejector (already described) are attached to this separate bolt face, and ride along with it in the right and left lug races, respectively.

Unlike the Mauser, Springfield, Enfield and Arisaka, this face, (or extreme forward portion of the bolt) which contains the firing pin port, does not turn with the bolt. Instead it remains in the same stance during the locking and unlocking motion of the bolt handle. It is kept so aligned during these operations by the action of the extractor and ejector, both of which remain in the lug races.

The advantages of this system are created by the small amount of friction encountered between the two polished steel surfaces of the bolt and bolt face assembly — as compared to that existing with the regular Mauser bolt face which twists against the head of a cartridge. Also this feature eliminates the need for an ex tractor collar and cut on the outside of the bolt, and for an ejector assembly in the receiver (the latter being theoretically less reliable than the type used in the Thirty Year Model).

But the faults of the system are obvious. It is unduly complicated and it has many small parts, difficult of manufacture. It increases the length of the bolt, which is a trend directly against important present day concepts of rifle design. And though some small advantage is gained by opening up the front end of the bolt in normal disassembly for cleaning; it is more than outweighed by the necessary use of two separate pieces in the bolt body, with small parts placed in the critical forward position where they are continually subject to heavy shock.

The bolt, after being removed from the rifle by depressing the bolt stop, is disassembled by first removing the “false face group” by rotating and pulling to the front. This group includes what I would call the bolt face, the extractor, and the ejector. These three parts are easily separated from each other — in fact they will fall apart when separated from the bolt. Next a tiny latch is depressed, a coin is inserted in the slot of the cocking piece screw (in same position as cocking piece head on Springfield) and it is turned counter clockwise about eight complete turns, which frees the threads on its forward end from engagement with the upper sear body inside the bolt’s rear half. After these eight turns the screw continues to rotate, clicking each time, but it will emerge no further. This is where the brass slug on the end of the cleaning rod comes into use.

Grasp the bolt in the left hand, handle end upward. Place the brass end of the rod against the tip of the firing pin in the forward end of the bolt. Then, holding the cleaning rod and bolt as a single rod (the firing pin will fit into a hole in the end of the brass slug), place the steel end of the rod on a hard surface and press downward on the bolt holding firmly onto the cocking piece hook the while [sic]. As this is done the firing pin spring will be compressed and the cocking piece screw will be gradually forced upward, at which time it will be discovered that the cocking piece screw is really in two pieces — being split down its center into two equal halves. These halves will fall apart, releasing their engagement with the grooved end of the firing pin rod, after which the firing pin rod and spring can be removed from the front end of the bolt and the upper sear body from the sear cut by merely lifting the bolt a bit farther and letting them fall out.

The entire bolt, disassembled, can be laid out in ten pieces, not including the small latch inletted and pinned permanently into one of the halves of the cocking piece screw. Assembly is accomplished by repeating the process inversely.

It can be seen at once that the Thirty Year Model is by no means as simple and rugged as a good military bolt action should be, and the principal objectionable complications seem to be in the design of the bolt — and nearly all of them in its front end. The lack of a camming action on down stroke of the bolt is another serious objection; and of course the difficulty of large manufacture attendant with utilization of such small parts — all machined and critical of fit — would be strongly felt by the factories.

The other objections are minor. If the weapon were equipped with an Arisaka bolt and ejector, and if it cammed on closing stroke it would be a good gun — a very good gun.

But then, if the weapon were so fitted, it would be an Arisaka, for those were the only modifications made when the Arisaka was adapted from this model.

All in all, the Thirty Year Carbine didn’t seem a bad weapon to me when I was sitting on the Guadalcanal beach, stripped to the waist, back resting against a coconut log, feeling the warm sun and breeze. I was lazily shooting at shark fins and floating coconuts; all the while looking out over the blue channel between Guadalcanal and Savo and reflecting happily that the dangerous part of the Guadalcanal fight was over. I felt so lazy that when I got through firing I handed the weapon to a native boy to clean, crawled into the shade, and stretched out on a blanket until dinner time.